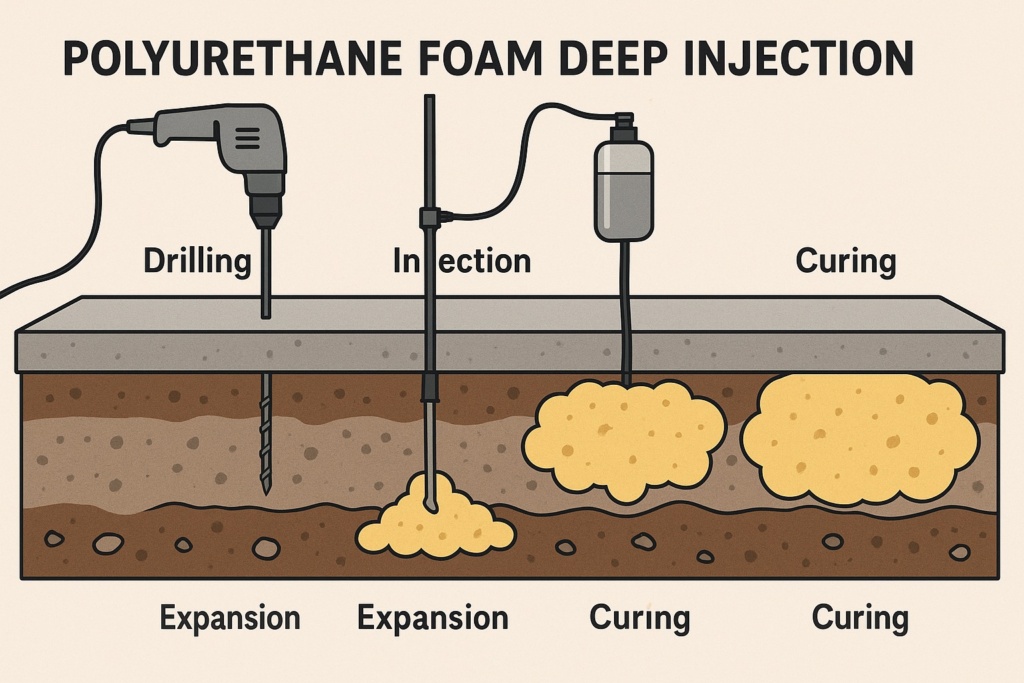

Polyurethane Ground Stabilisation (deep injection) is a construction and geotechnical method that uses expanding polyurethane foam to improve or stabilise soil and ground conditions.

The material is injected into the ground where it expands, hardens (cures) and binds loose soil, improving strength and stability.